Which brand of the wheeled hydraulic wood grabber is good?

2022-12-20

The working principle and application of PESCO hydraulic log grapple.

2022-12-20First of all, the PESCO scrap steel briquette dismantling machine generally consists of two parts: the host and the working device.

The working device of the PESCO scrap steel briquette dismantling machine adopts the structure of a “straight arm, curved bucket rod”. This type enables the PESCO scrap steel briquette dismantling machine to achieve the maximum grabbing radius and maximum grabbing height.

It is more suitable for long-distance loading and unloading and stacking high materials above the parking surface. The integral boom assembly is mainly composed of the integral boom and the boom cylinder. The overall boom is in the form of a straight boom,

The feature of the straight arm is that compared with the curved arm of the same specification, it can increase the maximum grab radius and maximum grab height of the steel grabber. The hinge point of the oil cylinder in the middle of the boom adopts the “integral hollow beam” type of cast-welded structure and the use of the integral hollow beam type of cast-welded structure. The strength of the overall boom is guaranteed, and the stress concentration point is dispersed at the same time, which also reduces the weight of the overall boom and achieves the purpose of increasing the weight of the material to be grabbed.

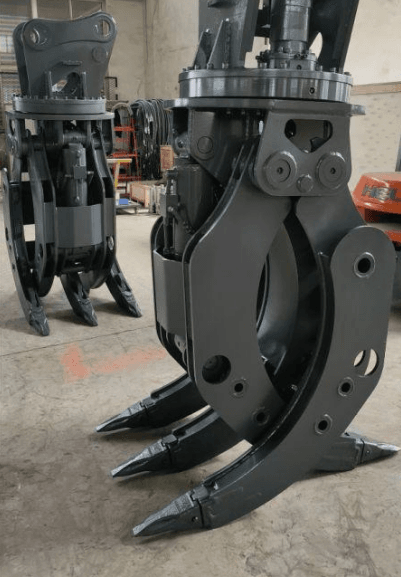

According to the working conditions of each construction site and the different needs of customers, the PESCO scrap steel briquette dismantling machine can replace booms and sticks of different specifications, and can also be equipped with different grabs according to different materials. Such as the plum blossom grab, the plum blossom grab assembly has the advantages of excellent stability, great closing force, fast closing speed, firm structure, large grab volume, lightweight, and small gap after closing, etc. Ensure economy of material handling payload. There are also different types of grabs such as fork buckets and electric suction cups, which can be widely used in steel plants, iron smelting plants to grab steel, as well as mines, and wharves. Grab loose materials such as coal, charcoal, slag, etc. in places such as railway transportation.

The PESCO scrap steel briquette dismantling machine can be configured with a fixed heightened cab or a hydraulically heightened cab according to customer needs, and then the heightened cab can improve the driver’s field of vision and facilitate operation.

At the same time, the driver’s cab adopts a streamlined appearance design, which is spacious and comfortable, shockproof and sound-proof; the seat can be adjusted freely in front and rear, up and down, and the backrest tilt, providing the driver with the best fatigue-free sitting posture; All instruments, alarms, and control handles are carefully arranged; the armrest pilot valve and foot pedal pilot valve are easy and accurate to operate; the driver’s cabin is equipped with a comfortable three-dimensional air supply cooling and heating air-conditioning system. It can provide a comfortable working environment around the clock; the driver’s cab is equipped with a protective cover to ensure safety, and the front window has a wiper, which is convenient for working on rainy days. The whole vehicle is equipped with lights to meet the requirements of night operation.

The entire driver’s cab embodies the humanized design and manufacture of man-machine integration.

The PESCO steel grabber meets the requirements of many countries for environmental protection, and at the same time effectively reduces the consumption of manpower. PESCO scrap steel briquette dismantling machine can complete two working cycles in one minute, which greatly improves work efficiency. It is a cost-effective machine.